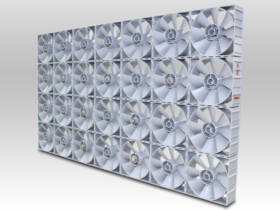

Adiabatic Discharge and Exhaust Air Cooling

Adiabatic exhaust air cooling uses rainwater for cooling buildings. The water is sprayed into the exhaust air current and cools it down. A heat exchanger then cools the warm supply air with the cold exhaust air. No exchange takes place between the two air currents. Heat recovery is all that is required to use the exhaust air cooling system.

Areas of Application

There is practically no limit to the number and types of application it can be used for. Adiabatic exhaust air cooling systems are proven and tested in industry, in the commercial sector and in public facilities.

The Benefits

The principle of adiabatic discharge and exhaust air cooling is economical and preserves resources. Significant savings can be made even at high temperatures when compared to conventional systems. The level of efficiency is so high that savings in electricity or teleheating can be made in the region of up to 30 or even 50 %.

The fact that rainwater has a low salt and limescale content means that it has an added benefit compared to drinking water in that it does not need to be desalinated. This effectively halves the amount of water that is required.

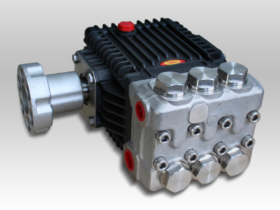

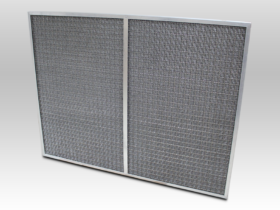

WinCool provides a system which thanks to its innovative technology makes best use of all the benefits of adiabatic exhaust air cooling. For example, a saturation of over 100 % RH can be achieved during high pressure cooling. Decades spent on research and developing the systems ensure that the energy and running costs are also low. Because the water in the exhaust air current is also a potential source of germs, our cooling systems fulfil strict hygiene norms and quality requirements.